Real-World Engineering: Smith’s Design Clinic

Research & Inquiry

Published May 10, 2019

Serena-Lian Sakheim-Devine ’19, who started developing her mechanical skills in elementary school during summer woodworking workshops, came to Smith “with the dream of doing my own engineering design.” Her ambition was realized this semester, when Sakheim-Devine and three Smith teammates in the engineering Design Clinic unveiled a plastic rod-scoring device they designed for Sanderson MacLeod twisted wire brush company in Palmer, Mass.

The device—built by the team of Sakheim-Devine and fellow seniors Ha Phuong Le, Mandira Marambe and Nina Shute—is designed to make small cuts in rods for twisted wire brushes used for taking gynecological cell samples. Such scoring indicates where the rods should be snapped in two after each sampling.

Each team member led a specific aspect of the project design: Le handled actuators, Sakheim-Devine the machining, Shute the blade durability testing and Marambe oversaw control.

“We needed each other to get this device working,” Sakheim-Devine said.

Sanderson MacLeod plans to incorporate the students’ work in setting up an in-house rod scoring process—a move that is expected to result in financial savings for the company.

The wire-brush team was one of nine presenting at the April 26 Design Clinic Celebration on campus. Projects completed by students in the two-semester course included, among other things, designs for a micromobility vehicle with Honda, culvert evaluation with the Northampton Department of Public Works, and manufacturing improvements with Collins Aerospace.

Susannah Howe—a senior lecturer in engineering who has led Smith’s Design Clinic since its inception 16 years ago—said the program offers students extended experience with “real-world engineering.”

“Our students are working with engineers in industry, practicing what it’s like to do engineering,” Howe said. “The heart of the program is that they have sponsor involvement and interest in their projects.”

Brian Chechile, director of manufacturing excellence for Sanderson MacLeod, praised the Smith team for their “ability to adapt, ask engaging questions—and their solution development.”

“The best thing about this project was watching the students grow,” Chechile added. “We will now take their design and modify and implement it on our production equipment.”

Smith team member Shute said the eight-month design process involved numerous mechanical functions, such as how to move individual rods into place for scoring.

“Our ‘Aha!’ moment came in the middle of spring semester,” said Shute, who will work as a quality engineer at Collins Aerospace after graduation. That’s when the students discovered that a component similar to a jeweler’s lathe could grip and rotate the plastic rods for scoring.

Marambe, who led the team’s efforts to incorporate automation into the design work, said it was rewarding to be able to present “not just a prototype” but an actual working device to the company.

For Le, a key takeaway was the importance of communication in engineering design work.

“Before, I didn’t have the experience of working directly with people from a company,” she said. “For this project I learned how to communicate with them. There was a lot of growth!”

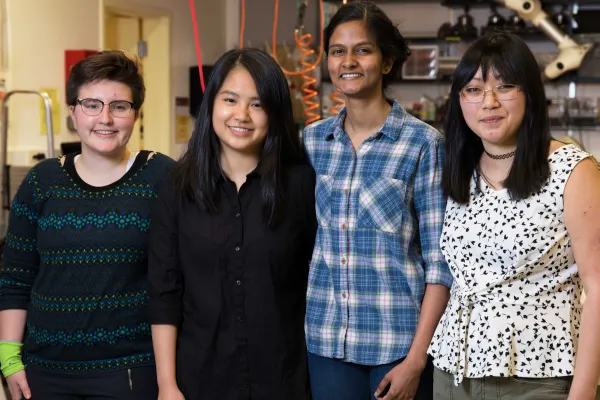

Smith seniors and members of Design Clinic team (from left) Nina Shute, Ha Phuong Le, Mandira Marambe and Serena-Lian Sakheim-Devine.